Superfine Pulverization German Tech Air Jet Mill

$13900-139000 /Set/Sets

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Air |

| Port: | qingdao |

$13900-139000 /Set/Sets

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Air |

| Port: | qingdao |

Model No.: UFM-17

Brand: Jingxin

Capacity (kg/h): kg/h

Feed Size (mm): mm

Crushing Fineness (mesh): mesh

Material: Sus316, Sus316l, Sus304l, Sus304, Other

Application: Medicine Processing, Chemicals Processing, Food Processing

Old And New: New

Types Of: Grinder

Place Of Origin: China

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food Shop, Energy &Amp; Mining, Food &Amp; Beverage Shops

Marketing Type: New Product 2020

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Engine, Motor, Gearbox

Diameter Of Grinding Road: 720-1200

The Layer Number Of Grinding Way: 3

Product Fineness (um): 12-45

Total Power: 100-185KW

Yield Of Heavy Calcium: 600-1800kg/h

| Selling Units | : | Set/Sets |

| Package Type | : | wooden packing or customer requirement |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

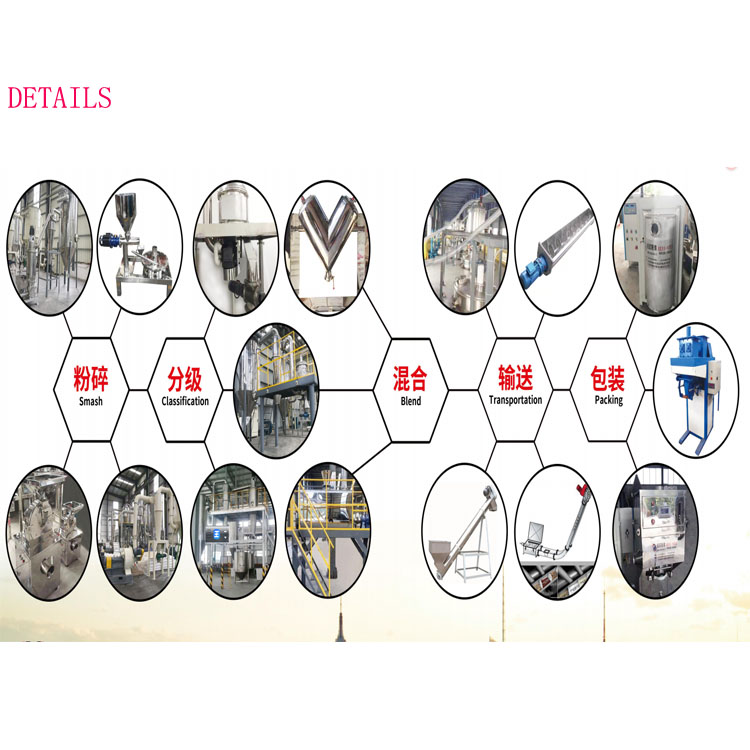

Our main products are Air Jet Mill, horizontal jet mill , vertical jet mill , lab jet mill, plat or spiral jet mill, Air Classifier, single or multiple rotor air Classifier, handstand air classifier, lab air classifier, ball grinding mill classifier, CJ series ultrafine jet mill, CJ traditional chinese medicine ultrafine jet mill, Dry Desulfurization Equipment,professional equipment for deep processing of cracking carbon black,lithium cathode material crusher equipment,lithium cathode material crushing classification professional equipment and so on.

The machine is dry roller grinding type, clever use of arc grinding channel, reasonable use of collision, rolling, grinding mechanism. Set crushing classification in one of the qualified fine powder extraction in time, coarse powder continue to grind, to avoid the material crushing, can replace Raymond mill to do ultrafine grinding.

Used in heavy calcium carbonate, kaolin, marble, barite, gypsus, calcium oxide, calcium hydroxide, activated carbon, pitch coke, cracking carbon black, graphite, etc.

JXM ring roller micro grinding (medium speed micro grinding) complete equipment includes: hammer crusher, bucket elevator, storage silo, electromagnetic vibration feeder, main engine, powder selection machine, diffusion type double cyclone powder collector, pulse Dust Collector, high pressure fan, muffler. The main motor drives the spindle and the turntable of each layer to rotate through the reducer, and the turntable drives dozens of ring rollers to roll and rotate in the magic ring raceway through the pin. Big materials of the crusher into small particles into the storage bin by elevator, electromagnetic vibrating feeder will material evenly to the centre of the wheel, on the material under the action of centrifugal force on the circle around, and falls within the possession ring raceway of stamping ring roll, roll grinding, grinding and crushing, the material after the first layer crushing and fall into the second and third layer, The suction effect of the high pressure centrifugal fan will draw the external air into the machine, and the coarse powder after the third layer of crushing will be brought into the powder selection machine. The vortex generated by the rotating turbine in the powder separator makes the coarse particle material fall back and grind again. The fine powder enters the cyclone powder collector with the air flow and is discharged by the discharge valve at the lower part, which is the finished product. The air flow with a small amount of fine dust is purified by the pulse dust collector and discharged by the fan and muffler.

| Type | JXM300 | JXM400 | JXM500 |

| Roller NO. | 15 | 21 | 30 |

| Diameter of grinding road | 720 | 900 | 1200 |

| The layer number of grinding way | 3 | 3 | 3 |

| Product fineness (um) | 12-45 | 12-45 | 12-45 |

| Total power | 100 | 135 | 185 |

| Yield of heavy calcium | 600-800kg/h | 1000-1300kg/h | 1500-1800kg/h |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.