circular disc type spiral jet mill

$8200-139000 /Set/Sets

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Air |

| Port: | Qingdao |

$8200-139000 /Set/Sets

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Air |

| Port: | Qingdao |

Model No.: QLMB-17

Brand: Jingxin

Capacity (kg/h): kg/h

Feed Size (mm): mm

Crushing Fineness (mesh): mesh

Material: Sus316, Sus316l, Sus304l, Sus304, Other

Application: Medicine Processing, Chemicals Processing, Food Processing

Old And New: New

Types Of: Grinder

Place Of Origin: China

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food Shop, Energy &Amp; Mining, Food &Amp; Beverage Shops

Marketing Type: New Product 2020

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Engine, Motor, Gearbox

| Selling Units | : | Set/Sets |

| Package Type | : | ACCORDING TO CUSTOMER'S REQUIREMENT |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

WORKING PRINCIPLE

The raw material is input from the hopper, sprayed into the crushing cavity, and the supersonic air flow ejected from the crushing nozzle forms a logistics, colliding with each other, friction and obtain the micro powder, the micro powder is imported into the center outlet, collected with the air discharge, the coarse powder is thrown to the crushing area due to centrifugal force to continue to crush.

CHARACTERISTICS

It is suitable for ultra-fine crushing of dry and brittle materials, and it is easy to obtain materials of several microns

● Because mainly by the powder between the grinding, the product is not easy to pollution, high purity;

● No running parts, in addition to the normal wear of the lining, other parts generally will not be damaged;

● Airtight dust free, environmental protection;

Low noise, no vibration, convenient disassembly and cleaning;

● Can achieve large capacity continuous production, high degree of automation:

● According to different properties of materials, select the corresponding lining materials (mainly around the crushing chamber and the part of the inlet and outlet pipes) to solve the hard materials (Moh hardness is not more than 9) and wall adhesive materials in the crushing caused by the problem.

WORKING PRINCIPLE

The raw material is input from the hopper, sprayed into the crushing cavity, and the supersonic air flow ejected from the crushing nozzle forms a logistics, colliding with each other, friction and obtain the micro powder, the micro powder is imported into the center outlet, collected with the air discharge, the coarse powder is thrown to the crushing area due to centrifugal force to continue to crush.

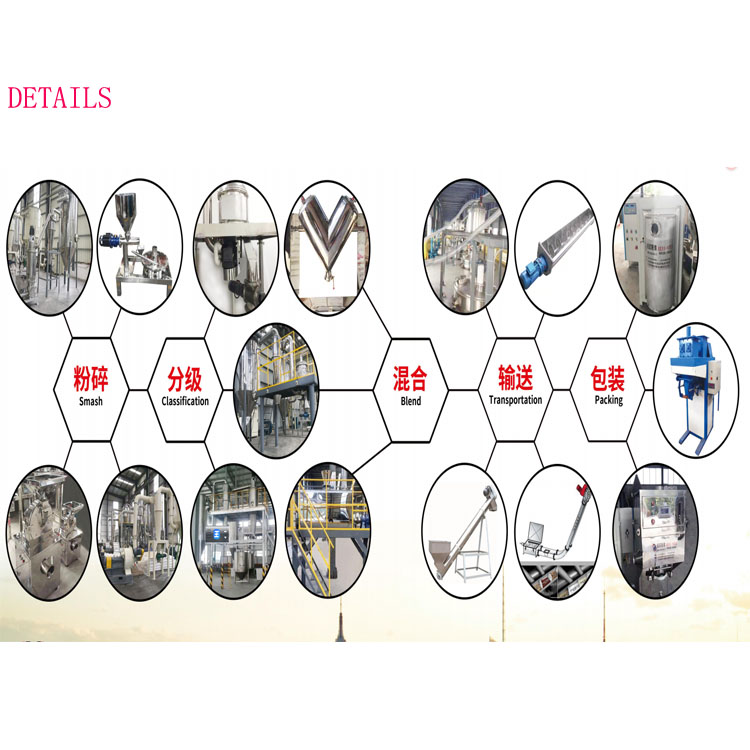

INFORMATION DETAILS

The crushing chamber of flat air jet mill has simple structure and low maintenance rate, so it is widely used. Structure: It is mainly composed of crushing chamber, nozzle mouth, discharge port air flow outlet, compressed air inlet, grading area, etc.

APPLICATION

● Non-metallic ore powder processing: kaolin, talc powder, graphite, light calcium carbonate, mica, vermiculite, spinel, attachorite, wollastonite, brucite, bentonite, etc.

● Chemical powder processing: aluminum hydroxide, silica gel, white carbon black, wood powder, epoxy resin, toner, foaming agent, magnesium hydroxide, cellulose, molybdenum trisulfide, antimony trioxide, titanium dioxide, alumina, dyes, pigments, etc

● Pesticide powder processing: carbendazim, methyl tobuzin, herbicide powder, insecticide powder, fungicide powder wettable powder, etc

● Pharmaceutical powder processing: green tea, salvianthus miltiorrhiza, pearl powder, terrapin powder, panax notoginseng, west green fruit, nimodipine, fenofiate, ibuprofen, bismuth nitrate, cortisone, penicillin, pollen, pearl powder, nimodipine equal

● Pigment powder processing: iron oxide, chromium oxide, phthalocyanine, cadmium red, cadmium blue, etc

● Battery material powder processing: lithium cobaltate, cobalt oxide, lithium manganate, manganese dioxide, lithium nickel cobaltate, lithium carbonate, coke, graphite, lithium iron phosphate, asphalt, composite materials, etc

● Flame-retardant material powder processing: magnesium oxide, magnesium carbonate, zinc oxide, zinc borate, magnesium hydroxide, etc.

Type QLMB-1.7 QLMB-3 QLMB-6 QLMB-10 QLMB-15 QLMB-20 QLMB-30 QLMB-40 Air pressure(Kgf/cm2) 6.5-12 Air consumption(m3/min) 1.7 3.0 6.0 10.0 15.0 20.0 30.0 41.4 power 11 37 45 79 90 132 210 270 Handling capacity 0.5-20 2.0-50 10-100 20-200 50-300 100-500 300-800 600-1200

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.